- Details

Pictured: A standard radiograph of The North wind (left) shows touched-up areas of the painting as dark patches, of interest to conservators; in the centre, the pre-restoration painting as viewed by the naked eye (centre); the image on the lower right shows the power of the Australian Synchrotron’s X-Ray Fluoresence Microscopy (XFM) beamline in revealing colour-coded detail of the metal composition of paint layers.

Following an intensive, year-long conservation project, one of Australia’s foremost Impressionist artists Frederick McCubbin will be seen in a new light as his painting, The North wind, c1888, returns to public display at NGV Australia today.

Working with the Australian Synchrotron and utilising its ability to produce light a million times brighter than the sun and record the X-ray fluorescence emitted, NGV researchers have imaged the pigments buried within the many layers of paint to reveal the painting’s secret history, no longer visible on the surface.

Images produced by the Australian Synchrotron’s X-Ray Fluorescence Microscopy (XFM) beamline revealed a lush and green landscape composition later replaced by McCubbin in favour of an arid landscape, a change suspected to have been made amid the centenary of settlement commemorations in 1888 and the emergent idea of the ‘Aussie battler’.

The high resolution images also confirmed the signature and much-speculated 1891 date depicted on the painting were added erroneously after early restoration attempts saw the painting cropped and the original signature and date removed. Analysis at the Australian Synchrotron showed the use of materials in The North wind is consistent with McCubbin’s work in the late 1880s and indicates the painting was most likely begun between 1887 and 1888.

Professor Andrew Peele, Director of the Australian Synchrotron says pixel-by-pixel scanning on the XFM beamline guided the restorative work of NGV conservators.

‘While the naked eye can differentiate between colours, and a standard X-Ray reveals further information about the depth and shape of the paint, only the powerful light of the synchrotron beam can colour-code and map the distribution of metals such as zinc, lead and iron in the pigment, enabling conservators to identify and remove touch-ups from the original.

‘As a national facility, the Australian Synchrotron is proud to improve understanding and contribute to the conservation of our collective cultural heritage.’

Tony Elwood, Director, NGV says the NGV’s conservation department is responsible for the care and restoration of more than 70,000 works of art.

‘Our conservators have partnered with scientists at the Australian Synchrotron to advance the use of state of the art imaging technology in the visual arts and created new research methods for art historians and conservators.’

Prior to entering the NGV’s collection in 1941 The North wind was subjected to significant restorations that altered the presentation of the artist’s original work, including a failed attempt to clean its surface, followed by considerable over-painting of McCubbin’s original composition. There was also evidence to suggest that the format of the picture has been modified and the original frame removed.

From today, a new interactive e-book will be on display at NGV Australia detailing the restoration process of McCubbin’s The North wind through interviews, text, images and videos. This display will be a new permanent feature of NGV Australia and showcase works from the NGV collection that have undergone conservation research.

Find out more:

Hear Dr Daryl Howard, Scientist on the XFM beamline describe how the Australian Synchrotron team helped NGV conservators restore The North wind, in an interview with Michael Varcoe-Cocks, Head of Conservation, NGV. Play video below.

Read the full story of The North wind’s journey back to glory in NGV Australia’s extensive e-book, produced with the support of the Bank of America Merrill Lynch Art Conservation Project. Click to view e-book >

Media coverage:

‘High-res imaging reveals Fred McCubbin's true painting’, Australian Financial Review, Thursday 3 December 2015.

‘Australian Synchrotron used to analyse pigments to restore Frederick McCubbin's The North Wind’, Sydney Morning Herald online, Tuesday 15 December 2015.

- Details

The stonefish is one of the world’s ugliest and deadliest fish. You’ll know if you step on one; the fish protects itself using 13 razor sharp venom filled spines capable of slicing through reef shoes. The resulting pain is crippling, can last for days and may result in amputation of a limb or death -- a torturous venom worth avoiding.

Monash University researchers have solved the X-ray crystal structure of the lethal factor present in stonefish venom. Their discoveries have provided unexpected insight into a crucial human immune response that is responsible for the failure of up to 30 per cent of bone marrow transplant therapies for treating leukaemia.

The structural insights obtained from stonefish venom are now being used to develop immunosuppressants to improve the success rate of transplant therapies.

The work, published today in PNAS (Proceedings of the National Academy of Sciences of the United States of America), reveals that the lethal component of stonefish venom, a protein called Stonustoxin, is an ancient relative of the human immune protein perforin.

In humans, perforin is an essential weapon unleashed to destroy virally infected and cancerous cells.

Perforin proteins attach themselves to a diseased cell and assemble to form giant ring shaped holes, or pores, on the cell surface. Each pore contains around 20 perforin proteins that stick together in a symmetrical fashion. The pores are big enough to allow toxins to enter the cell, killing it from within.

How these pores form is a mystery but the work on stonustoxin has revealed a key part of the pore assembly mechanism.

To make their discovery, the team used powerful synchrotron radiation to visualise the atomic structure of stonustoxin. Crucially, they found that the toxin contains two perforin-like proteins stuck together. By seeing how two of the proteins first interact, the researchers can build on this to understand how the full assembly of 20 perforin molecules forms a complete pore.

Unravelling the structure of the stonefish’s lethal toxin was carried out at Monash University and the ARC Centre of Excellence in Advanced Molecular Imaging. The leading authors of the study were Dr Andrew Ellisdon, Dr Sheena McGowan and Professor James Whisstock.

“The lethal factor in stonefish venom is like a loaded gun: ready to fire as soon as it is injected into the foot of an unsuspecting victim,” says co-lead author Dr Sheena McGowan.

In humans unwanted or excessive perforin activity is responsible for a range of medical problems including pancreatic cell destruction in type I diabetes and the rejection of bone marrow transplants in the treatment of leukaemia.

Accordingly, an international group of researchers, led by the Peter MacCallum Cancer Institute and including Monash based Professor Whisstock and his team, are working to develop perforin inhibitors.

“Already the structure of stonustoxin is starting to inform our drug development program,” says co-lead author Professor Whisstock. “Now we understand the very first stages of perforin pore formation. This type of mechanistic information is extremely useful in developing new strategies to inhibit perforin itself.

“People who step on a stonefish suffer agonising pain because the lethal stonustoxin protein attacks nerves. The treatment for envenomation includes an antivenom together with soaking the wound in non-scolding hot water – the latter treatment unravels the venom and stops it punching holes,” he says.

The work conducted at the Imaging Centre used major national research platforms, including the Australian Synchrotron, and Monash University Ramaciotti Centre for Cryo-Electron Microscopy.

Content courtesy of the ARC Centre for Advanced Molecular Imaging

Media coverage:

‘Deadly stonefish discovery could reduce transplant rejection rate in cancer patients’, on ABC radio’s World Today, Wednesday 2 December 2015

- Details

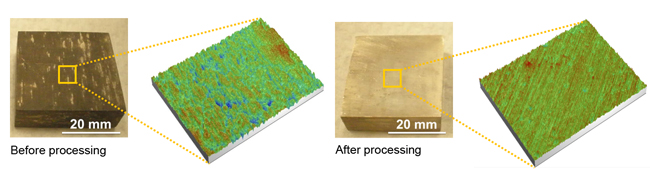

Pictured: The surface condition of two samples of the magnesium-lithium alloy following immersion for 20 hours in salt water, one after being heat-treated and water quenched, and the other without processing. In previous magnesium-lithium alloys, irreversible corrosion would have set in after such time, but clearly visible in this optical profilometer image, the surface of the processed alloy remains in near pristine condition.

Researchers led by a team at UNSW Australia have used the Australian Synchrotron to turn the discovery of an ultra-low density and corrosion-resistant magnesium alloy into the first step toward mass-producing ‘stainless magnesium’, a new high-strength, lightweight metal, paving the way for cars, trucks and aeroplanes that can travel further distances on less petrol.

The magnesium-lithium alloy weighs half as much as aluminium and is 30 per cent lighter than magnesium, making it an attractive candidate to replace these commonly used metals to improve fuel efficiency and greatly reduce greenhouse gas emissions from transport vehicles.

The findings, published in the current edition of Nature Materials with researchers from Monash University in Melbourne, describe how the alloy forms a protective layer of carbonate-rich film upon atmospheric exposure, making it immune to corrosion when tested in laboratory settings.

Professor Michael Ferry, from UNSW’s School of Materials Science and Engineering, says this formation of a protective surface layer can be considered similar to the way a layer of chromium oxide enables the protection of stainless steel.

‘Many similar alloys have been created as researchers seek to combine the incredible lightness of lithium with the strength and durability of magnesium to develop a new metal that will boost the fuel efficiency and distance capacity of aeroplanes, cars and spacecraft.

‘This is the first magnesium-lithium alloy to stop corrosion from irreversibly eating into the alloy, as the balance of elements interacts with ambient air to form a surface layer which, even if scraped off repeatedly, rapidly reforms to create reliable and durable protection.’

Professor Ferry, senior author of the paper led by Dr Wanqiang Xu also from UNSW, says this excellent corrosion resistance was observed by chance, when his team noticed a heat-treated sample from Chinese aluminium-production giant, CHALCO, sitting, inert, in a beaker of water.

‘To see no corroded surfaces was perplexing and, by partnering with scientists on the Powder Diffraction (PD) beamline at the Australian Synchrotron, we found the alloy contains a unique nanostructure that enables the formation of a protective surface film.

‘Now we’ve turned our attention to investigating the molecular composition of the underlying alloy and the carbonate-rich surface film, to understand how the corrosion process is impeded in this “stainless magnesium”.’

The transport sector accounts for 90 megatonnes (90 billion kilograms) of greenhouse gas emissions in Australia each year, or 16 per cent of Australia’s total; road vehicles account for 77 megatonnes and aviation eight tonnes.

Professor Nick Birbilis, School of Materials Science and Engineering at Monash University, says viewing unprecedented structural detail of the alloy through the Australian Synchrotron will enable the team, involving researchers from Monash University, CHALCO, and Nanjing University of Technology in China, to work toward commercialising the new metal.

‘Through our close collaborator, Dr Yang Xiao, we have strong ties to the Zhengzhou Light Metals Research Institute of CHALCO in China.

‘We’re aiming to take the knowledge gleaned at the Australian Synchrotron to incorporate new techniques into the mass-production of this unique alloy in sheets of varying thickness, in a standard processing plant.

‘These panels will make many vehicles and consumer products much lighter and, eventually, just as durable as today’s corrosion-resistant stainless steel, another example of how advanced manufacturing is unlocking the potential of materials that have been under investigation, in too narrow a manner, for centuries.’

Media coverage:

· Discovery of ‘stainless magnesium’ on ABC radio's ‘AM’, Thursday 26 November 2015